In order to produce high-quality special shapes out of refractory concretes and masses, the company TERMOMATIK-TOPLOTEHNIKA has built a production and dryout line, which consists of:

– Production Hall (15,0 x 10,0 m) and covered storage area (5,0 x 8,0 m)

– Two countercurrent mixers for preparation of refractory concrete. The capacities of mixers are 500/250 and 250/130

liters (working space/working capacity)

– Three vibrating tables with a working surface of 1,200 x 1,200 mm, with a variable number of oscillations of a fixed vibrator

– Three concrete vibrators with vibrating shafts Ø30 – Ø60 mm

– Bridge crane with load capacity of 50,0 kN (5.000 kg) and span 8,0 m, for transportation of materials, manufactured shapes and pallets

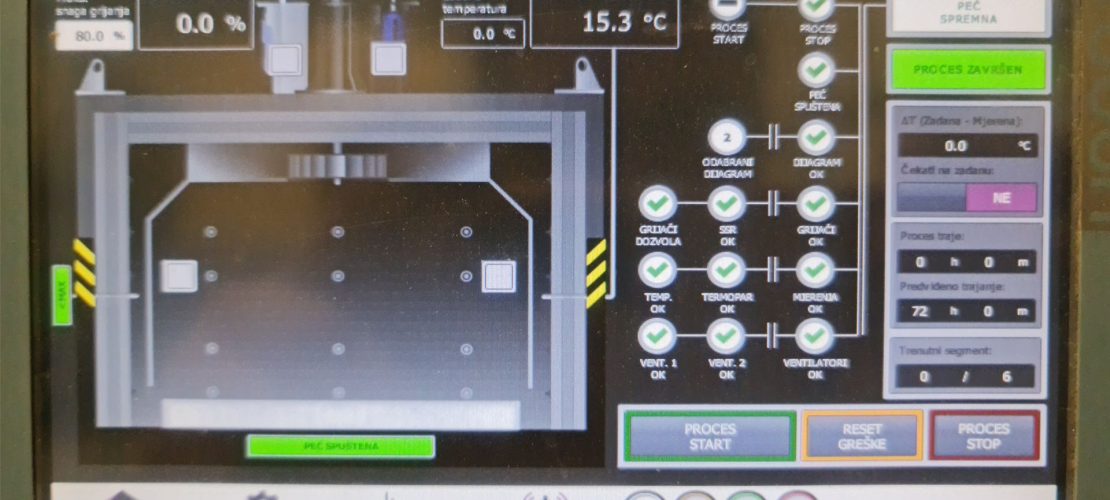

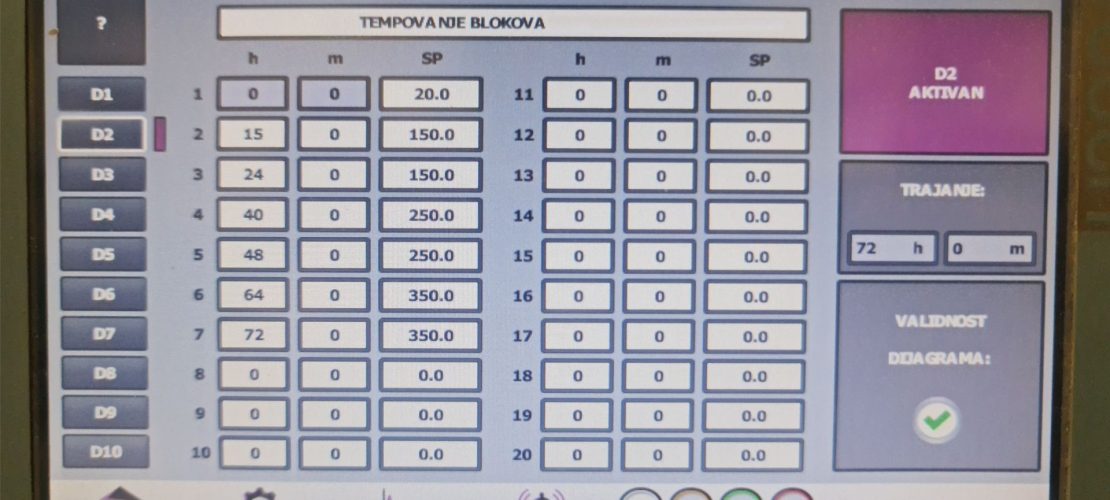

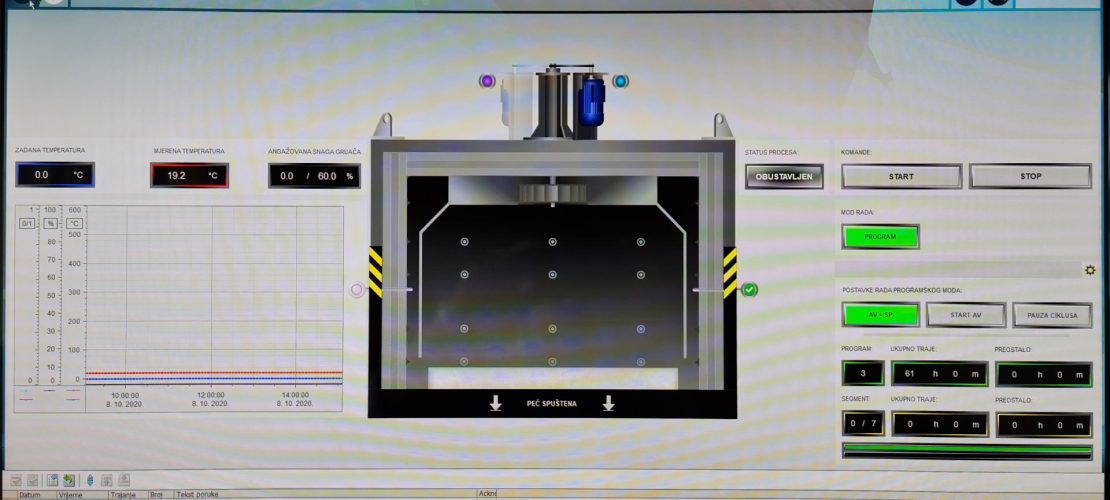

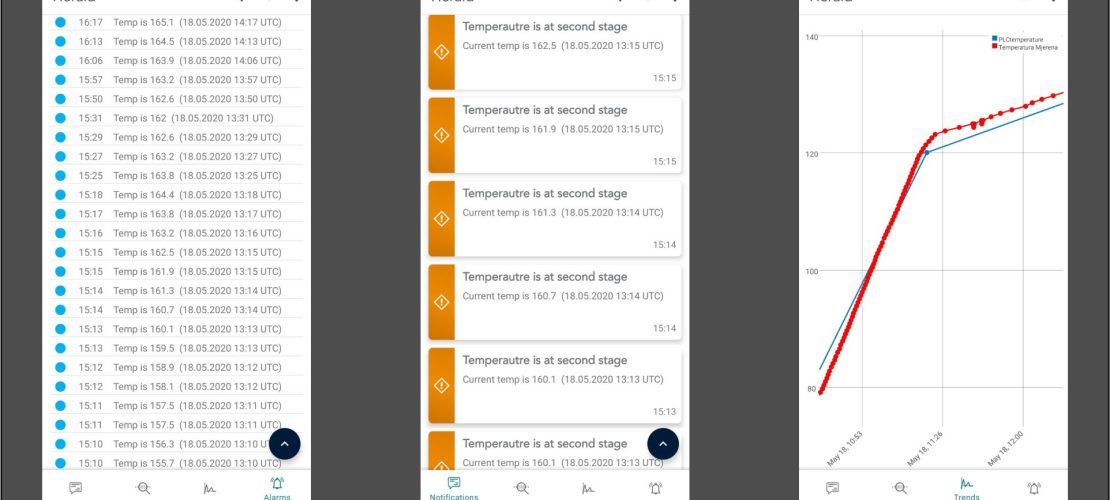

– Chamber Furnace for dryout of preformed shapes. Two furnace hearths ensure the continuity in the prefabrication process.